Tractor with a flashing AdBlue light and a potential immobilization issue on the side of the road could be resolved by AdBlue removal services from a us at JTPlantHire.ie.

Here’s a likely situation:

Scenario: Contaminated AdBlue or SCR System Malfunction

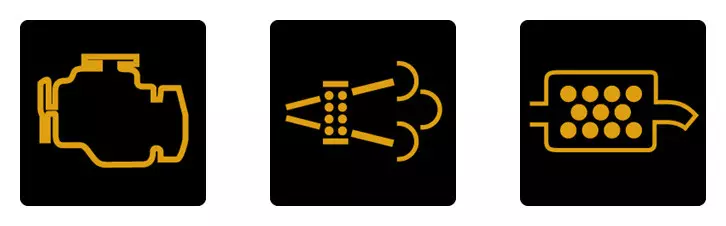

A common and critical situation where AdBlue removal becomes the key solution is when the AdBlue (Diesel Exhaust Fluid or DEF) system fails due to contamination or a component malfunction that triggers the warning light and a severe engine derate, or even complete shutdown, when the vehicle is far from a service depot.

The Situation

A modern tractor, equipped with a Selective Catalytic Reduction (SCR) system (which uses AdBlue), is performing fieldwork or transporting equipment. Suddenly, the AdBlue warning light starts flashing (indicating a critical fault, low quality, or imminent engine derate). Shortly thereafter, the engine may enter a limp-mode (severely reduced power) or stop running completely while the tractor is partially blocking a road.

The Problem

- Likely Cause: The operator may have inadvertently filled the AdBlue tank with diesel or water, or the existing AdBlue has become crystallized or contaminated within the tank or supply lines due to a faulty cap or storage issue. Alternatively, a sensor (like the $\text{NO}_x$ sensor) or the dosing pump has failed, and the SCR system is detecting an issue that the Engine Control Unit (ECU) interprets as a serious emissions violation.

- Immediate Consequence: The tractor’s ECU has registered a fault severe enough to prevent a restart or keep the power output extremely limited to comply with emission regulations. A simple top-up won’t fix contamination, and replacing the faulty sensor/pump is a complex roadside repair.

The Key Solution from JT Plant Hire.ie: AdBlue System Flush and Fault Reset

In this precise roadside breakdown scenario, AdBlue removal and system cleaning is often the most efficient immediate fix offered by a mobile plant repair service:

- Removal & Flush: The service technician from JT Plant Hire.ie would use specialized equipment to completely drain and remove the contaminated or crystallized AdBlue from the tank, lines, and possibly the dosing module. They may then flush the system with de-ionized water or a specific cleaning agent.

- Diagnostic & Reset: The technician uses diagnostic tools (ECU reader) to pinpoint the exact fault code, clear the stored fault, and attempt to reset the SCR system.

- Refill: The system is then refilled with fresh, certified quality AdBlue.

Why this is the Key Solution:

- Speed: It addresses the contamination/system failure immediately at the breakdown site, allowing the tractor to be restarted and driven (even if only to a depot) without a complex and expensive towing operation or a lengthy wait for specialist parts.

- Mitigation: If the fault was due to contamination, the flush prevents further damage to expensive SCR components like the dosing pump and injector, which can be ruined by incorrect fluids or crystals.

- Immobilization Bypass: By correcting the fluid and resetting the fault, it bypasses the ECU’s immobilization mandate, getting the machine moving again quickly, which is critical for road safety and operational efficiency.